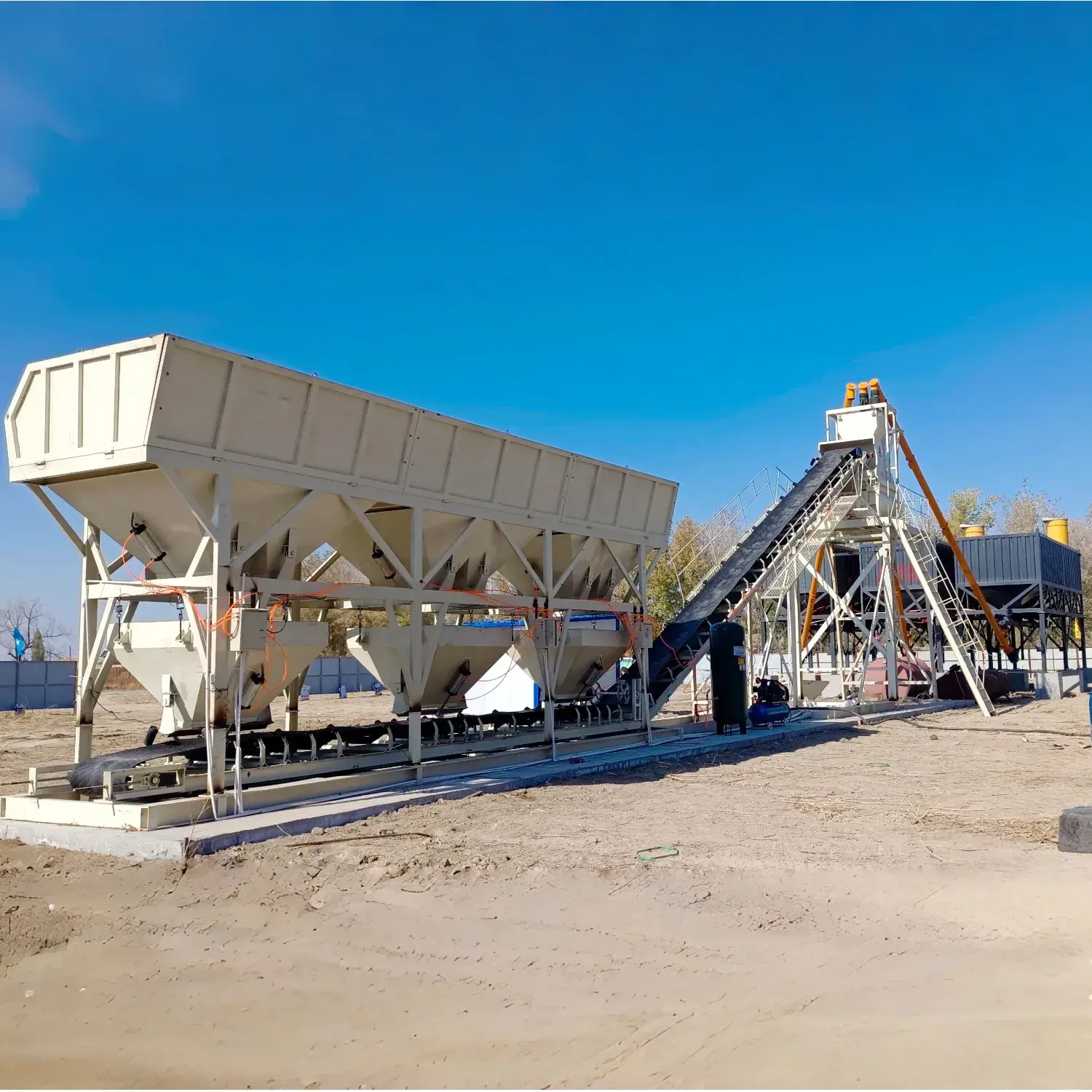

Foundation Free Concrete Batching Plant

Model: MHZS60,MHZS90,MHZS120,MHZS180,etc

Theoretical Productivity(m³/h): 60-180

Mixer Type: Twin-shaft horizontal

Aggregate Batching Machine: PLD1600–PLD4800

The foundation-free concrete batching plant is a flexible, fast-deploy solution for concrete production. Since it does not require a conventional reinforced concrete foundation, installation is greatly simplified, shortening setup time and improving deployment efficiency.

The product line currently features four flagship models: MHZS60, MHZS90, MHZS120, and MHZS180. Each model’s core architecture includes a mixing platform steel frame and a foundation-free steel base frame, supplemented with efficient belt conveyors and an independent weighing system to guarantee precise weighing and consistent material supply.

Introduction

The foundation-free concrete batching plant is a flexible, fast-deploy solution for concrete production. Since it does not require a conventional reinforced concrete foundation, installation is greatly simplified, shortening setup time and improving deployment efficiency.

The product line currently features four flagship models: MHZS60, MHZS90, MHZS120, and MHZS180. Each model’s core architecture includes a mixing platform steel frame and a foundation-free steel base frame, supplemented with efficient belt conveyors and an independent weighing system to guarantee precise weighing and consistent material supply.

Main Components of Foundation Free Concrete Batching Plant

Mixing system

Mix various raw materials in the mixing main unit to form uniform concrete. The mixing main unit adopts a twin-shaft forced mixer with high mixing efficiency and good mixing uniformity.

Dosing system

The aggregate silo of ready-mixed concrete is a device for storing aggregates such as sand and stone. Various raw materials are weighed according to accurate proportions and transported to the main mixer for mixing.

Cement Silo

Horizontal cement silo stores cement and prevents moisture intrusion to ensure that the cement does not get damp or deteriorate during storage. The screw conveyor transports the cement from the silo to the weighing bucket.

Control system

Automatically control and manage the entire concrete batching plant, including control of raw material metering, conveying, mixing and other processes, as well as data recording, fault alarm and other functions.

Weighing system

Weighing sensors provide accurate measurement for aggregates, cement, water and additives. Batching indicators can display real-time weight data during operation.

Aggregate feeding system

Bucket elevators lift aggregates for storage or mixing. Bucket elevators are compact options for vertical aggregate transmission.

Technical Specification

| Model | MHZS60 | MHZS90 | MHZS120 | MHZS180 |

|---|---|---|---|---|

| Capacity | 60 | 90 | 120 | 180 |

| Concrete mixer | Twin shaft concrete mixer | |||

| Concrete mixer Model | JS1000 | JS1500 | JS2000 | JS3000 |

| Aggregate feeder | Belt Conveying Concrete Batching Plant | |||

| Aggregate batching machine | PLD1600 | PLD2400 | PLD3200 | PLD4800 |

| Storage bins quantity(m³) | 4 x 8 | 4 x 12 | 4 x 15 | 4 x 20 |

| Discharging volume(L) | 1000 | 1500 | 2000 | 3000 |

| Charging volume(L) | 1600 | 2400 | 3200 | 4800 |

| Discharging height(m) | 4.1 | 4.1 | 4.1 | 4.1 |

| Weighing system | Water, Cement, Additive; Weighing precision: ±1% | |||

| Air system | Air compressor, etc | |||

| Control system type | Computer auto-control module (PLC can be optional item) | |||

| Warranty | 12 months after erection | |||

| After-sale service | Erection & commissioning, operator training | |||

Application

The MHZS series foundation-free concrete batching plants are designed to deliver high flexibility, fast installation, and reliable performance across a wide range of construction projects. Thanks to their modular and foundation-free design, they are ideal for use in the following scenarios:

Infrastructure Construction – Suitable for highways, bridges, tunnels, airports, railways, and other large-scale infrastructure projects requiring continuous and stable concrete supply.

Commercial Concrete Production – Perfect for ready-mix concrete suppliers and contractors needing high productivity with minimal site preparation.

Temporary or Short-Term Projects – The rapid installation and easy relocation make MHZS plants ideal for temporary construction sites or projects with tight deadlines.

Remote or Limited-Access Areas – Especially practical for regions where traditional foundation work is difficult or costly, such as mountainous or undeveloped areas.

Precast Concrete Production – Widely used in precast factories for producing concrete elements like panels, pipes, and blocks with consistent quality and precise batching.

Emergency and Disaster-Relief Projects – The quick deployment capability ensures timely concrete supply for urgent infrastructure restoration or emergency engineering works.